When it comes to precision cutting, fiber laser cutting technology has become a game-changer. With its exceptional accuracy, speed, and versatility, fiber laser cutting machines have revolutionized the manufacturing industry. In this comprehensive blog post, we will delve into the world of fiber laser cutting, covering everything you need to know about this advanced cutting method, its benefits, applications, and why it’s a go-to choice for industries worldwide.

The First Appearance of the Laser

Before we talk about fiber lasers, we first need to understand what a laser is. Laser is an abbreviation for “Light Amplification by Stimulated Emission of Radiation”. Lasers were first theorized by American physicists Arthur Schawlow and Charles H. Townes in 1958, and the first actual laser was built in 1960 by Theodore Maiman, a ruby laser.

The Birth of Fiber Laser

As laser technology continued to develop, scientists began to explore new laser media and structures. Among them, the fiber laser emerged in the early 1970s. This type of laser utilizes optical fiber as the gain medium and achieves high integration, efficiency, and effectiveness through specialized design.

Fiber lasers are noted for their combination of high power, superior beam quality, and high efficiency. Furthermore, they are compact in size, durable, and functional across a vast range of wavelengths.

Since its inception, laser applications have extended across numerous sectors, ranging from medicine, communication, and manufacturing to entertainment. Specifically, fiber lasers have become the preferred tool for industrial tasks such as cutting, welding, and drilling, primarily because of their high power density and unparalleled beam quality.

Classifications and Products

Fiber lasers can be classified in several ways. Some of the most prevalent classifications are outlined below. For a closer look at products that integrate fiber lasers, see the links provided:

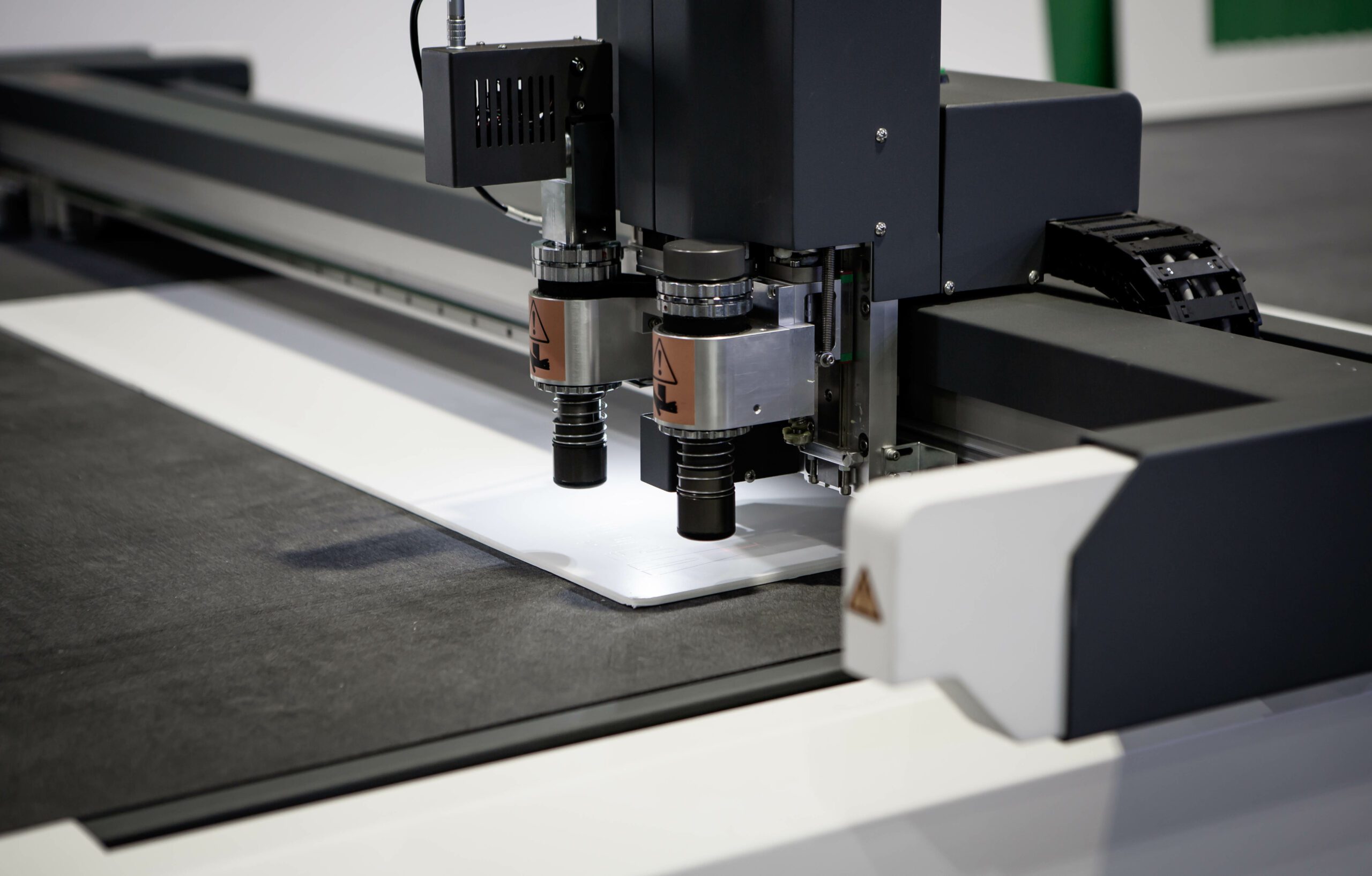

How Does Fiber Laser Cutting Work?

Fiber laser cutting has become a cornerstone in modern manufacturing, mainly due to its unmatched precision, efficiency, and speed. Let’s explore the process in detail.

Generation of the Laser Beam

The core of the machine is the optical fiber, usually doped with rare-earth elements such as ytterbium. Research indicates that ytterbium-doped fibers can amplify up to 1000 times when appropriately stimulated. Introducing energy excites the doped ions. As they return to their resting state, they emit photons, allowing rapid photon production.

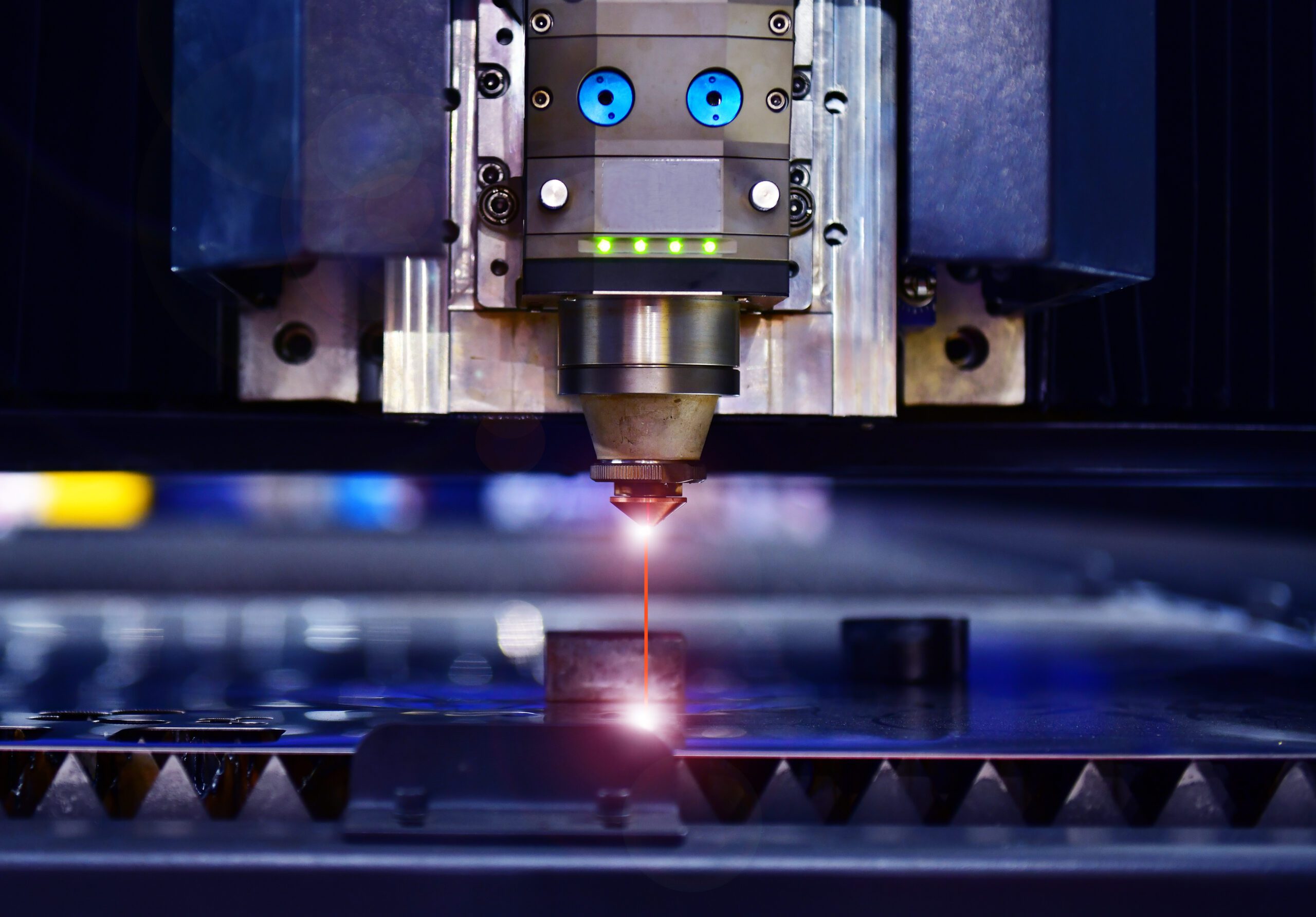

Beam Delivery and Focusing

The beam produced traverses the optical fiber. Due to total internal reflection within the fiber, energy loss is minimal. Exiting the fiber, the beam encounters focusing optics, concentrating it to a fine point, magnifying its intensity.

Interaction with the Material

The laser’s energy density can swiftly melt or vaporize materials. For example, steel with a 1mm thickness can be cut at speeds up to 10m/min with a 1kW fiber laser. Assist gases, typically oxygen or nitrogen, play dual roles: evacuating molten material and inducing an exothermic reaction that aids the cutting process.

Movement and Control

CNC precision offers positional accuracy of up to 0.05mm. Such precision is especially crucial in industries like aerospace. Modern feedback mechanisms, using optical sensors, can detect deviations in cut quality and make real-time adjustments.

Cooling System

Given the intense heat, cooling is vital. Cooling systems, often circulating water or specialized coolants, mitigate potential overheating. A typical 1kW fiber laser machine would have a coolant flow rate to ensure the core temperature stays below operational limits.

Learn more about The Advantages of Laser Cutting Machine in Industrial Applications.

Industrial Applications of Laser Cutting Machines

Metal Fabrication

In the metal fabrication industry, fiber laser cutting has become the go-to method for precise and efficient cutting. It enables the creation of intricate designs, precise parts, and complex shapes in metals, making it indispensable for industries such as automotive, aerospace, and architecture.

Metal laser cutters equipped with fiber laser technology are capable of handling various metals, including stainless steel, aluminum, copper, and more. They offer exceptional precision and speed, allowing for the production of intricate components and parts with tight tolerances. Whether it’s cutting sheet metal for automotive body panels or fabricating intricate metal parts for aerospace applications, fiber laser cutting machines deliver exceptional results.

Woodworking and Furniture Design

Fiber laser cutting has found its way into the woodworking industry, revolutionizing furniture design and production. It enables precise cuts in various types of wood, allowing for intricate patterns, custom designs, and detailed engravings. Learn about specifications for laser wood cutters

Signage and Display Manufacturing

The versatility of fiber laser cutting has revolutionized industries, especially in the realm of signage and display manufacturing. For those diving deep into this transformation, our article, “A Deep Dive into Acrylic Signage: Benefits, Techniques, and the Role of Fiber Laser Cutting”, provides an insightful exploration.

The versatility of fiber laser cutting makes it an excellent choice for creating signage, displays, and decorative items. It delivers precise and clean cuts on materials like acrylic, PVC, and foam, resulting in high-quality and visually appealing end products.

Acrylic laser cutters equipped with fiber laser technology offer exceptional precision and versatility in the signage and advertising industry. They enable the creation of intricate signage, logos, lettering, and displays with clean edges and smooth surfaces. Whether it’s for retail signage, exhibition displays, or promotional materials, fiber laser cutting machines ensure the production of visually stunning and professional-looking products.

Electronics and Electrical Components

Laser cutting machines are instrumental in the production of electronics and electrical components. They provide high-precision cutting of materials like printed circuit boards (PCBs), ensuring accurate and intricate designs. Laser cutting machines play a vital role in manufacturing electronic devices, such as smartphones, computers, and consumer electronics, by enabling precise and efficient production processes.

Medical Device Manufacturing

The medical industry has a growing need for precision and reliability, and a detailed discussion of laser cutting machines for the production of medical devices and equipment can be found in our article “How Fiber Laser Cutting is Transforming Medical Device Manufacturing“.

The medical industry also benefits from laser cutting machines in the production of medical devices and equipment. These machines allow for the precise cutting of materials used in devices like stents, surgical instruments, and implantable components. The accuracy and cleanliness of laser cuts contribute to the quality and functionality of medical devices, making laser cutting an essential process in this field.

Small Business and Entrepreneurship

Fiber laser cutting machines have become increasingly accessible to small businesses, thanks to their affordability and compact size. These machines empower entrepreneurs to start their own laser cutting businesses, offering customized products, personalized designs, and unique creations. We offer fiber laser cutting machines to meet specific needs and production capacities. How Much Do Laser Cutting Machines Cost?

Advantages of Fiber Laser Cutting

Unparalleled Precision

Fiber laser cutting machines offer exceptional precision, allowing for intricate and complex cuts with tight tolerances. This level of accuracy ensures high-quality results and minimizes material waste.

High-Speed Cutting

With their cutting-edge technology, fiber laser cutting machines boast impressive cutting speeds. They can swiftly process materials, improving productivity and reducing production time, making them ideal for large-scale projects or tight deadlines.

Versatility Across Materials

One of the key advantages of fiber laser cutting is its ability to cut a wide range of materials. From metals like stainless steel, aluminum, and copper to non-metallic materials such as wood and acrylic, fiber laser cutting machines can handle diverse materials with precision and ease.

Clean and Burr-Free Cuts

Fiber laser cutting produces clean and smooth cuts, eliminating the need for additional post-processing. The absence of burrs or rough edges reduces the time and effort required for finishing, resulting in higher efficiency and cost savings.

Fiber Laser Cutting Machines – Spearheading Precision Manufacturing with Andelaser

In the realm of modern manufacturing, the fiber laser cutting machine isn’t merely a tool – it’s the cornerstone of precision, speed, and versatility. The laser cutting machine industry, replete with constant innovation, is undergoing a significant transformative phase. As the worldwide demand for high-quality manufacturing solutions escalates, the importance of dependable laser cutter suppliers and manufacturers can’t be overstated. Amidst the vast array of laser cutter manufacturers, Andelaser, a distinguished laser cutter company hailing from China, is marking remarkable progress with its groundbreaking offerings.

Tailored Solutions

Understanding the distinct needs of every industry, Andelaser provides laser cutter custom solutions, ensuring precise alignment with specific demands.

Bulk Production Capabilities

For enterprises requiring laser cutter bulk procurements, Andelaser’s comprehensive infrastructure guarantees prompt deliveries without any sacrifice on the quality front.

Wholesale and Vendor Collaborations

Being a paramount laser cutter wholesale distributor, Andelaser has forged strong alliances with vendors worldwide, cementing its reputation in the laser cutter China industry.

Legacy of Excellence

Among the community of laser cutter creators, Andelaser’s dedication to innovation and superior quality distinguishes it. Their internal team is perpetually evolving designs and strategies, pushing the innovation envelope.

While the market is teeming with laser cutter vendors, associating with a reputable laser cutter producer like Andelaser assures alignment with a paradigm of unmatched quality and groundbreaking innovation. Andelaser shines as a guiding light for enterprises scouting for elite laser cutting machine solutions.

Whether your enterprise’s requirement orbits around laser cutter bulk acquisitions or tailored solutions, Andelaser remains the trusted ally on this quest for precision and novel innovation.

For deeper insights, queries, or to delve into partnership avenues, contact the Andelaser team directly.