Laser cutting has emerged as a versatile and precise method for cutting various materials. From metals to non-metals, laser cutting machines offer exceptional accuracy and the ability to create intricate shapes. In this blog post, we will delve into the workings of laser cutting machines, exploring the technology behind them and the factors that contribute to their effectiveness.

What Is Laser Cutting?

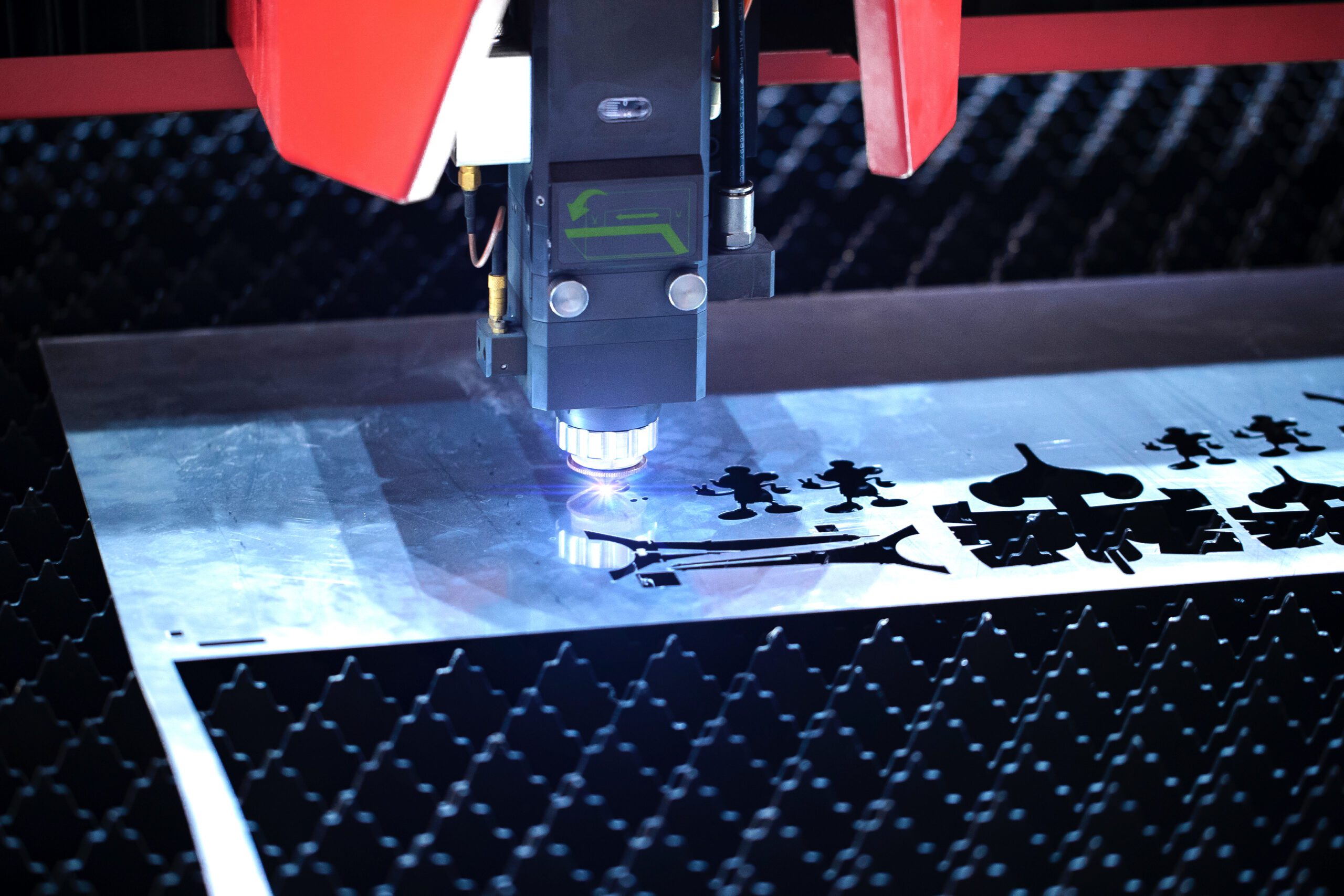

Laser cutting is a process that utilizes a focused laser beam to trim down or cut materials, replacing traditional drilling and shaping methods. This technique is highly versatile, and capable of cutting a wide range of materials with varying thicknesses. By harnessing the power of laser beams, laser cutting machines provide exceptional precision and enable the creation of complex shapes and intricate designs.

Laser Cutting Machines

Laser cutting machines are advanced tools used in various industries for precise and efficient material cutting. They are manufactured by specialized companies that design and produce cutting-edge laser cutting equipment.

Precision and Accuracy

Laser cutting machines are known for their unparalleled precision and accuracy. They offer precise control over the cutting process, allowing for intricate and detailed cuts. The precision of laser cutting machines is measured in terms of positional accuracy and repeatability, which can reach sub- millimeter levels.

Cutting Speed and Efficiency

Laser cutting machines are designed to optimize cutting speed and efficiency. They utilize high-powered lasers that can rapidly cut through materials with minimal heat-affected zones. The cutting speed depends on factors such as the material type, thickness, and desired cutting quality.

Versatility of Materials

Laser cutting machines are capable of cutting a wide range of materials, making them highly versatile tools. They can handle materials like metals (stainless steel, mild steel, aluminum, etc.), wood, plastics, fabrics, paper, and cardboard. Laser cutting machines can adapt to different materials by adjusting the laser power, focal length, and cutting parameters.

Automation and CNC Control

Many laser cutting machines are equipped with computer numerical control (CNC) systems, enabling automation and precise control over the cutting process. CNC control allows for the programming of complex cutting patterns and shapes, ensuring consistent and accurate results.

Integration and Customization

Laser cutting machines can be integrated into production lines and workflows, enhancing efficiency and productivity. They can also be customized to meet specific manufacturing requirements, including the size of the working area, laser power, cutting speed, and additional features such as rotary attachments for cylindrical objects.

Note: Laser cutting machines are manufactured by specialized companies that are dedicated to developing and producing cutting-edge equipment. These manufacturers employ advanced technologies, engineering expertise, and quality control processes to ensure the reliability, performance, and safety of their machines.

If you are interested in laser cutting machines or looking for a reputable laser cutting machine manufacturer, please contact us for a quote.

Why Lasers Are Used for Cutting

Laser cutting machines have become increasingly popular across various industries due to their exceptional capabilities and advantages over traditional cutting methods. Let’s explore in detail why lasers are the preferred choice for cutting, particularly when it comes to metal plates.

Unparalleled Accuracy

Laser cutting machines offer unparalleled accuracy, ensuring precise cuts with tight tolerances. The use of highly focused laser beams allows for intricate detailing and the ability to achieve complex shapes that would be challenging or impossible with conventional cutting methods. For those who are curious about the broader applications and advantages, “激光切割机在工业应用中的优势” provides a comprehensive overview.

Laser cutting machines can achieve positioning accuracy within a range of 0.05 mm to 0.1 mm, enabling precise and repeatable cuts. This precision plays a significant role, especially in metal engraving. For more insights on this, one can delve into “Laser Cutting Machines – Metal Engraving Guide“.

For those interested in the different types of laser cutting machines and their working principles, “Exploring the Various Types of Laser Cutting Machines” offers a deep dive into the technical nuances of these machines.

Excellent Cut Quality

One of the key advantages of lasers for cutting metal plates is the excellent cut quality they deliver. The following factors contribute to the high-quality cuts achieved by lasers:

- Small Kerf Width: Laser beams have a small focal spot size, typically in the range of 0.1 mm to 0.4 mm. This narrow beam width results in a small kerf width, minimizing material wastage and allowing for intricate cuts.

- Minimal Heat-Affected Zone (HAZ): Laser cutting generates minimal heat, minimizing the thermal impact on the surrounding material. This results in a small HAZ, which reduces the risk of material distortion, warping, or damage, particularly in heat-sensitive materials.

Efficient Cutting of Small Holes

Laser cutting machines excel at cutting small holes with precision. Traditional drilling methods can be challenging when it comes to creating small holes, but lasers offer a more efficient solution.

Laser cutting machines can achieve hole diameters as small as 0.1 mm, depending on the material and laser system used. This capability is crucial in applications where precision is paramount, such as aerospace, electronics, and medical industries.

Versatility with Different Metal Types

Laser cutting machines demonstrate exceptional performance across a wide range of metal types, including mild steel, stainless steel, and aluminum. Each metal type presents its own challenges, but lasers are well-equipped to handle them.

- Mild Steel: Laser cutting provides precise and clean cuts on mild steel, allowing for intricate shapes and designs. The heat generated by the laser beam initiates an oxy-fuel burning process, where pure oxygen is used as the cutting gas.

- Stainless Steel: Laser cutting is highly effective for stainless steel, ensuring clean cuts without affecting the material’s corrosion-resistant properties. The laser beam melts the stainless steel, and high-pressure nitrogen is used to blow away the molten metal.

- Aluminum: Laser cutting offers excellent results on aluminum plates, with high precision and minimal thermal distortion. The laser beam melts the aluminum, and nitrogen is used to remove the molten metal from the kerf.

The combination of exceptional accuracy, excellent cut quality, efficient hole cutting, and versatility with different metal types makes laser cutting machines the preferred choice for various industries. Whether it’s achieving intricate detailing, precise cuts, or efficient production processes, lasers deliver reliable and high-performance results.

How Does Laser Cutting Work?

The laser cutting process begins with the generation of a high-intensity laser beam. Commonly used lasers in the industry include CO2 laser machines and fiber laser machines. CO2 lasers generate a laser beam in the infrared part of the light spectrum, which is invisible to the human eye. The laser resonator creates the beam, which then travels through the machine’s beam path. Along the way, mirrors or “beam benders” may redirect the beam before it is focused onto the material. Just before hitting the material, the focused laser beam passes through the bore of a nozzle, alongside a compressed gas such as oxygen or nitrogen.

Working Principles of Laser Cutting Machines

CO2 Lasers

CO2 lasers use a gas mixture of carbon dioxide, nitrogen, and helium as the laser medium. These lasers emit a high-energy laser beam in the infrared wavelength, typically around 10.6 micrometers. The CO2 laser beam is guided through a series of mirrors and directed onto the material being cut. The high-power laser beam vaporizes, melts, or burns through the material, resulting in precise and clean cuts.

Fiber Laser Cutting Machines

Fiber lasers employ a solid-state laser medium made of rare-earth-doped fibers, such as erbium, ytterbium, or neodymium. These lasers generate laser beams with a wavelength range of 1.0 to 1.1 micrometers, which is well-suited for metal cutting applications. The fiber laser beam is transmitted through a fiber optic cable and delivered to the cutting head, where it is focused onto the material. The high-energy density of the fiber laser beam rapidly melts and removes the material, allowing for accurate and efficient cutting.

Beam Focusing

In the laser cutting head, the laser beam is precisely focused using a special lens or a curved mirror. This step ensures that the focus spot shape and energy density are consistent, perfectly round, and centered within the nozzle. The ability to concentrate the large laser beam into a single pinpoint is crucial for achieving efficient cutting. The focal point determines the spot size and the intensity of the laser beam at the material’s surface. The spot size typically ranges from 0.1 mm to 0.4 mm, depending on the system and application. The energy density, or power per unit area, is maximized at the focal point, allowing for efficient material removal.

Localized Heating

When the focused laser beam hits the material, the high power density causes rapid heating, melting, and, in some cases, vaporization of the material. The exact process depends on the material being cut:

- Mild Steel: When cutting mild steel, the heat generated by the laser beam initiates an oxy-fuel burning process. Pure oxygen is used as the cutting gas, which reacts with the hot metal to create an exothermic reaction, effectively burning through the material.

- Stainless Steel or Aluminum: In the case of stainless steel or aluminum, the laser beam simply melts the material. High-pressure nitrogen is then employed to blow the molten metal out of the kerf, resulting in a clean and precise cut.

Beam Movement

A CNC (Computer Numerical Control) laser cutter utilizes precise movement of the laser cutting head over the metal plate, following the shape of the desired part. The movement is controlled by a computer program that specifies the cutting path. A capacitive height control system maintains an accurate distance between the nozzle and the plate being cut. This distance is crucial as it determines the focal point’s position relative to the plate’s surface. By adjusting the focal point above, at, or below the surface of the plate, the quality and characteristics of the cut can be influenced. The movement speed of the cutting head can vary depending on the material and desired cut quality. It can range from a few millimeters per second to several meters per second.

Laser cutting offers precise and intricate cutting capabilities, allowing for complex shapes and designs with exceptional accuracy. The ability to control the beam’s intensity, focus, and movement enables efficient and reliable cutting across a wide range of materials.As a leading manufacturer of CO2 laser machines and fiber laser machines, we offer a wide range of models designed to meet your specific needs. Visit our website to learn more about our cutting-edge laser cutting machines.

Frequently Asked Questions (FAQ) about Laser Cutting Machines

Q: How do you maintain a CNC laser cutting machine?

A: Proper maintenance of a CNC laser cutting machine is essential for optimal performance and longevity. Here are some maintenance tips:

- Regularly clean the machine, including the laser optics, lenses, and cutting bed, to remove dust and debris.

- Check and clean the ventilation system to ensure proper airflow and prevent overheating.

- Inspect and replace worn-out or damaged components, such as belts, bearings, and laser tubes.

- Calibrate machines regularly to maintain accuracy and precision and keep machines lubricated.

- Please refer to the CNC laser cutting machine maintenance guide.

- Follow a preventive maintenance schedule to address any potential issues before they escalate.

Q: What are 5 materials that can be laser cut?

A: Laser cutting is a versatile process that can be applied to various materials. Here are five common materials that can be laser cut:

- Metals: Such as stainless steel, mild steel, aluminum, brass, and copper.

- Woods: Including plywood, MDF, hardwood, and veneer.

- Plastics: Such as acrylic, polycarbonate, ABS, and PVC.

- Fabrics: Including cotton, polyester, nylon, and leather.

- Paper and cardboard: Used for precise cutting and intricate designs.

Q: What materials are not safe to laser cut?

A: Laser cutting is not suitable for all materials, and some can be hazardous or produce harmful byproducts when cut. Materials that are generally not safe to laser cut include:

- PVC (Polyvinyl Chloride): It releases toxic chlorine gas when cut.

- Vinyl and synthetic materials: They can release toxic fumes and produce a corrosive residue.

- Fiberglass: Cutting fiberglass can release harmful particles and fibers.

- Polystyrene foam: It can melt, catch fire, and release toxic fumes.

- Reflective materials: Such as metals with highly reflective surfaces, can cause damage to the machine and affect the cutting process.

More information on unsafe materials for laser cutting, including causes and potential hazards.

Q: What is the biggest advantage of a laser cutter?

A: The biggest advantage of a laser cutter is its exceptional precision and versatility. Laser cutting machines offer the following benefits:

- High precision: Laser beams can cut intricate shapes and produce fine details with excellent accuracy.

- Versatility: Laser cutters can work with a wide range of materials, including metals, woods, plastics, fabrics, and more.

- Clean and precise cuts: Laser cutting leaves minimal residue, resulting in clean edges without the need for additional finishing.

- Non-contact process: The material being cut is not physically touched, reducing the risk of damage or contamination.

- Automation and efficiency: Laser cutters can be programmed to cut multiple parts simultaneously, increasing productivity and reducing labor requirements.

Learn about the advantages of laser cutting machines and their impact on various industries.