Laser cutting machine manufacturers tell everyone that metal laser cutting machines are important equipment for sheet metal processing. The correct use of laser cutting machines from laser cutting machine manufacturers is also an important prerequisite for increasing their service life. Therefore, after purchasing the machine, you must master the standard and standardized machine operating procedures and methods to reduce the failure rate and increase the service life. Below we will introduce the standard and standardized operating procedures of the laser cutting machine:

First of all, you must strictly abide by the regulations and follow the principles of turning on and off laser cutting equipment. Never forcibly turn off or turn on the laser cutting machine equipment.

Secondly, employees are not allowed to operate the machine without training. They can only operate on the machine after being fully trained.

Third, during the working process of the metal laser cutting machine, outsiders are not allowed to approach the operating table and operating table, and the core operations must be completed by professionals;

Fourth, adjust the optical path of the machine tool, use follow-up methods to adjust the cutting head, and enforce precise follow-up control procedures to ensure human-machine safety.

Fifth, every time you turn on the machine, you need to return to the reference point, check and process the focusing lens, calibrate the coaxiality of the beam nozzle, turn on the cutting auxiliary gas, and the pressure in the bottle should not be less than 1Mpa;

Sixth, check the external light path protective gas, freezer, cooling channel, air compressor, freeze dryer and drainage filter of the laser cutting machine equipment once a week.

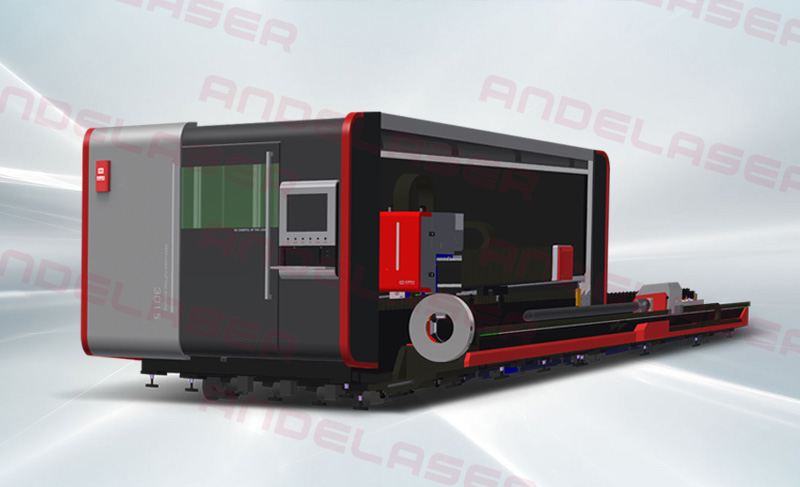

Features of metal laser cutting machine:

1. Determine the size of the bracket layout according to the size of the metal laser cutting machine. Only brackets suitable for this size can function as a metal laser cutting machine;

2. Ensure that the metal laser cutting machine can be placed on the bracket, stop running at high speed and stably, and ensure that the metal laser cutting machine can be placed stably on the metal laser cutting machine;

3. In order to ensure the connection between the frame of the metal laser cutting machine and each component, stable connections can make the operation of the metal laser cutting machine more stable.

The above is a detailed introduction to the installation of the metal laser cutting machine frame. Through the above methods, the metal laser cutting machine can be stopped and run more stably.