Laser Cleaning Machine

Application scenarios :

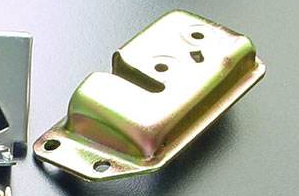

Rust Removal on Metal Surface

Paint Removal

Oil Removal

Surface Coating Treatment

Cleaning on Welding Mark

Stone Cleaning

Rubber Mold Cleaning

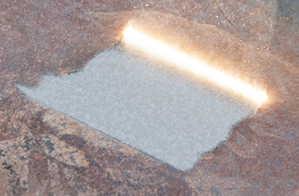

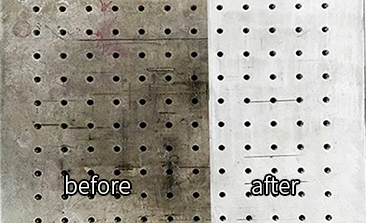

The laser cleaning machine has the characteristics of no grinding and non-contact. It can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc. Application effects include: rust removal, paint removal, oil removal, cultural relic restoration, glue removal, coating removal, and plating removal

Product features :

Ande Laser Cleaning Machine

6 Advantage· Make Cleaning Easier

Fast

Stable

Good Quality of Beam

High Accurcacy

Less Comsumables

Reasonable Configuration

Principle of laser cleaning

Laser cleaning technology refers to the use of high-energy laser beams to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface evaporates or peels off instantly, and effectively removes the surface attachment or surface coating of the cleaning object at a high speed, so as to achieve a clean process. It is a new technology based on the interaction effect between laser and matter.

Can be automated. High cleaning efficiency. No chemical cleaning solution is required. Less consumables

Real-time monitoring of cleaning results, which can achieve specific location and size cleaning.

The mode can be switched arbitrarily for operation. Other cleaning modes can also be customized according to specific requirements.

The interface is clear and concise. The operation is convenient, and various parameters can be set by yourself to realize the control of the galvanometer of the laser.

Why Choose Laser Cleaning Machine?

Non-contact cleaning, no damage to the part

Accurate position cleaning, beam size adjustable

No chemical cleaning fluid, less consumables

Technical Parameters:

Laser power

1000W/1500W/2000W

Laser wavelength

1080 NM±5NM

Length of fiber

Standard 10M

Laser

Continuous

Cooling method

Water cooling

Temperature range of working environment

10~40 ℃

Humidity range of working environment

< 70% No condensation

Power supply

AV220V/50Hz

Cleaning gun

Handheld

Scanning width

0-300mm( depends on the focus length installed)

F400: 0-150mm

F600:0-225mm

F800:0-300mm

Cleaning gun weight

0.7kg

Largest supporting air pressure

15bar

Cleaning Samples :

Laser application technology, innovator of change, intelligently changing manufacturing, intelligently innovating life

Professional team

Research and development

Logistics export

Factory base

At any time, if you need us, please call the 24-hour after-sales hotline : 400 8617 288

After-sales manager phone number : +86-750-3582689

Mail:info@ande-laser.com

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.