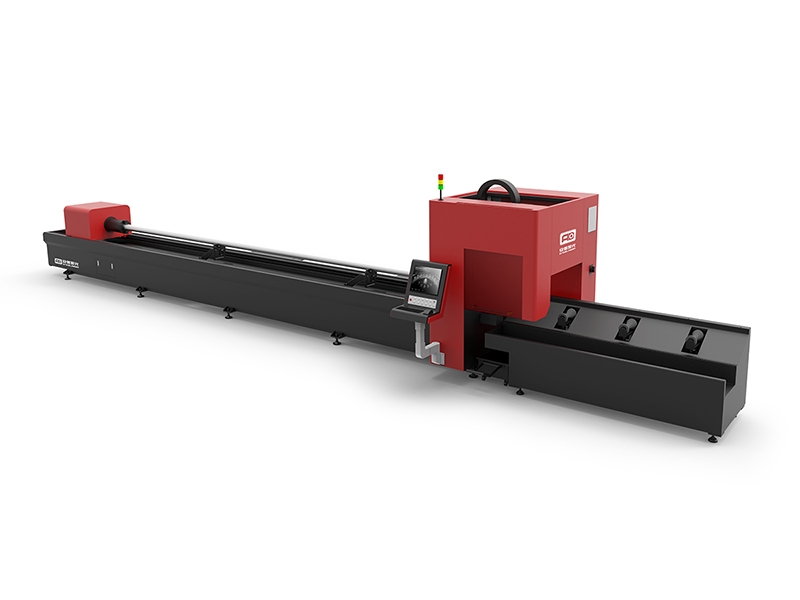

Four skills that must be mastered by laser tube-cutting machine for easy tube-cutting. When the traditional punching equipment processes holes on the tube, the hole surface will be depressed, the hole position will be inaccurate, and the hole surface will have burrs. Due to the flexibility of laser cutting Therefore, conventional tube-cutting has also begun to be processed by fiber laser tube-cutting machine. Using laser tube-cutting machine to open holes, the cut product not only has a smooth section, but also can flexibly change the processing aperture to meet the diverse needs of the factory. However, machining round holes with a laser cutting machine also requires some skills. Knowing the following four points can make the process of machining laser holes smoother.

1. Pay attention to the parameter error of the servo motor

Occasionally elliptical or irregular phenomenon occurs in the round hole, which is related to the mismatch of the XY axis motion, and the direct cause of the mismatch of the XY axis motion is the improper adjustment of the servo motor parameters. Therefore, the quality of the round hole cut by the laser tube-cutting machine also has certain requirements for the servo motor.

During the air-blowing process when using the laser tube-cutting machine to cut holes, when the air pressure is too small, there will be slag scraping and carbonization at the edges, and if the pressure is too large, it is easy to burst holes. Therefore, it is required that the craft proofer cooperates with the machine, and selects the appropriate air pressure with experience, so as to make the cut round hole more full.

3. Pay attention to the aperture size of the cutting. The laser cutting machine cutting circular hole ratio is 1:1, that is to say, the ratio of aperture to plate thickness is 1:1, that is to say, the larger the aperture, the more high-quality circular holes can be cut. much easier. Otherwise, when the energy of the fiber laser cutting machine is insufficient, the cutting holes are prone to breakpoint residues and round holes that are not round.

4. The accuracy error of the guide rail and the lead screw leads to the hole-cutting accuracy not reaching the ideal value

If the parameter error of the servo motor affects the cutting quality, then the accuracy of the guide rail and the lead screw will directly cause the accuracy of the round hole to fail to meet expectations. This is related to the strength of laser-cutting machine manufacturers. Usually, powerful manufacturers use high-quality accessories, so this phenomenon generally does not occur!

The above four points are the precautions that affect the hole-cutting of the laser tube-cutting machine. When the hole-cutting effect of the laser tube-cutting machine is not ideal, you can also refer to the above precautions to eliminate the problems during use.

Laser tube-cutting machine manufacturer Ande Laser Intelligent Equipment (Guangdong) Co., Ltd. is a laser equipment manufacturer integrating R&D, production, and sales, mainly engaged in laser cutting machines, laser tube-cutting machines, laser welding machines, and laser marking machines. And other series of equipment, welcome to consult and buy.