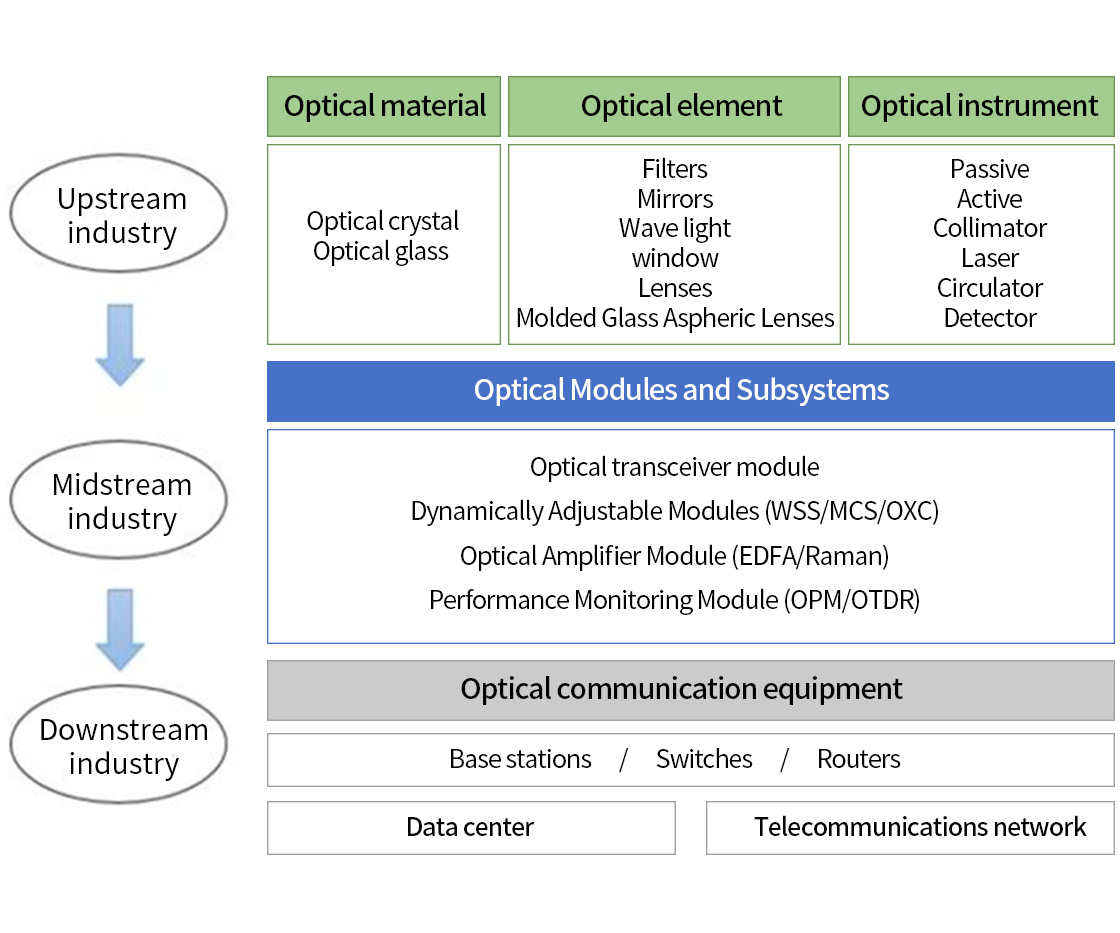

To understand the application of laser welding in the optical communication industry, first look at a picture and intuitively understand the situation of an upstream and downstream industry chain in the optical communication industry.

Since the chip is the most difficult product in the optical module industry chain, after the bare chip and the wiring board are micro-interconnected, they need to be sealed in a plastic, glass, metal or ceramic shell through packaging technology to ensure that the semiconductor integrated circuit chip is in the Working normally under various harsh conditions, laser welding is mainly used in this process.

In the industry, the traditional optical communication device packaging technology generally uses UV glue to bond and fix the device at the joint surface. First, the UV glue is dotted to the joint of the device, and then cured by ultraviolet light. This device connection method has many drawbacks, such as limited curing depth; limited by the geometry of the device; the glue will not cure where the UV light cannot illuminate. Laser welding, a new type of welding technology, has the advantages of firm welding, minimal deformation, high precision, fast speed, and easy automatic control, making it one of the important means of optical communication device packaging technology.

Laser welding is more and more used in the packaging of optical communication devices, and it also drives the demand for laser welding machines. Ande Laser Intelligent Equipment (Guangdong) Co., Ltd. is a laser equipment manufacturer integrating R&D, production and sales. Laser cutting machine, laser pipe cutting machine, laser welding machine, laser marking machine and other series of equipment, focusing on the research and development of products with stable performance and excellent quality, committed to providing systematic laser intelligent manufacturing solutions for small and medium-sized enterprises around the world, welcome to all walks of life Consult to buy.

In the industry, the traditional optical communication device packaging technology generally uses UV glue to bond and fix the device at the joint surface. First, the UV glue is dotted to the joint of the device, and then cured by ultraviolet light. This device connection method has many drawbacks, such as limited curing depth; limited by the geometry of the device; the glue will not cure where the UV light cannot illuminate. Laser welding, a new type of welding technology, has the advantages of firm welding, minimal deformation, high precision, fast speed, and easy automatic control, making it one of the important means of optical communication device packaging technology.

Laser welding is more and more used in the packaging of optical communication devices, and it also drives the demand for laser welding machines. Ande Laser Intelligent Equipment (Guangdong) Co., Ltd. is a laser equipment manufacturer integrating R&D, production and sales. Laser cutting machine, laser pipe cutting machine, laser welding machine, laser marking machine and other series of equipment, focusing on the research and development of products with stable performance and excellent quality, committed to providing systematic laser intelligent manufacturing solutions for small and medium-sized enterprises around the world, welcome to all walks of life Consult to buy.

Part of the content of this article is organized from the network sharing, if there is any infringement, please contact the editor to delete it.