Technical Parameters

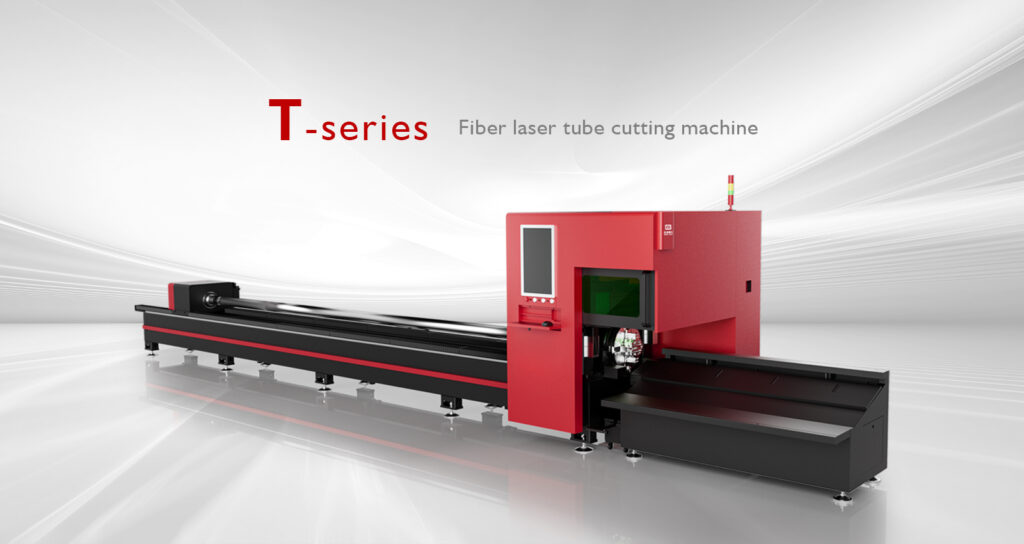

Model No.

ADT6022

ADT6016

ADT6012

Tube Diameter

φ10-220mm □10-150mm

φ10-160mm □10-110mm

φ10-120mm □10-80mm

Max Tube Weight

200kg

150kg

100kg

Chuck Rotational Speed

100m/min

Maximum Movement Speed

100m/min

Maximum Acceleration

1.0G

Laser Power

1000W-3000W

Multiful function & application to ensure high effiency

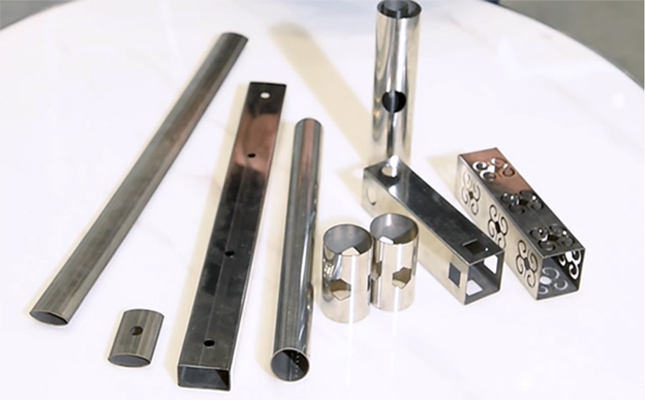

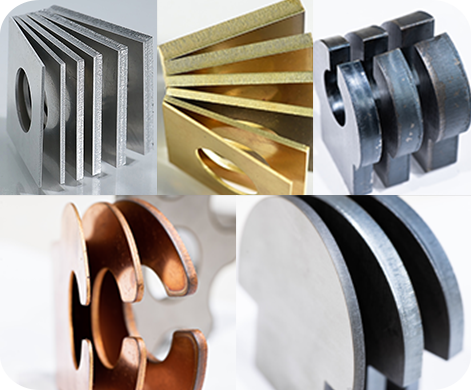

• Wide range application, suitable for various pipe materials such as round pipe, square pipe, oval pipe, and special-shaped pipe; Stainless steel, carbon steel, aluminum, copper, and other metal materials applicable.

Fully Automatic Pneumatic Heavy-Duty Type Chuck

• Automatic tube detection, no need to change clamps manually. Adjust the clamping tube according to different tubes, and at the same time, it will not deform the tube due to over-clamping.

• Choose a heavy-duty chuck. The heavy-duty chuck avoids the problem of large accuracy errors in the chuck caused by overweight pipes.

• The chuck has a longer service life

• The chuck has greater clamping force, to prevent the chuck claws from loosening during the rotation of heavy pipes.

High Quality Configuration

• Power operating range:10%~105%

• Light beam mass: BPP<2.5

• Service life of pumping source: 100,000h

• Maintenance free

• The collimator lens and focus lens are equipped in a drawer installation way, which is convenient for maintenance and replacement.

• Adopting a water-cooling heat sink inside to reduce the temperature of the cutting head to improve its service life.

Imported Component Parts

Original imported Helical Gear Rack and Linear Guide Rail

• Smooth transmission.

• Quiet, non-polluting, reliable, and long-lasting

• Achieve high precision and speed in the cutting process.

• Excellent quality and stability, under international standards.

Precision System andElectrical Parts

• High precision and speed, large inertia ratio.• Stable performance and durability.

• Excellent dynamic response.

• Closed loop control method

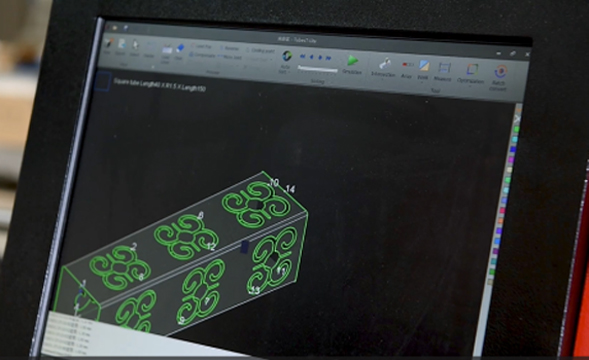

Professional Control Software for Tube

• The workpiece with a stable deviation of the tube surface, can effectively compensate for the regular cutting deviation, reduce the accuracy requirement of the raw material, and reduce waste.

• Using the cutting head to align the tube head can effectively reduce the time of manual alignment and reduce the front-end waste of manual alignment

Professional Water Chiller

• High precision temperature control function. Temperature control accuracy can reach ±1°C High temp. for QBH connection/ optics and low temp. for laser devices.

• Multiple alarm protection: The laser will stop working once it receives the alarm signal from the water chiller for protection purposes.

• Equipped with water pressure gauges, drain outlet with valve, and universal wheels. Water pres.sure gauges help monitor the discharge pressure of the water pump while universal wheels facilitate the moving of the chiller.

• Dualinlet and dual outlet connector& level gauge equipped. The Chiller inlet connects to the laser outlet connector. The Chiller outlet connects to the laser inlet connector.

• Cooling fan of famous brand installed. With high quality and low failure rate.

• Customized dust gauze is available and easy to take apart.

Segmented variable diameter wheel

Ande Services

Quality Control

Ball screw installation test

Laser collimator detectsguide line

Rack gear parallelism test

Marble feet for lathe bedverticality tesr

3 axes coordinate meter tests coordinate setting precision

Quantity production with skilled technique and advanced

Every tiny parts is detected with many times

Measure sample geometrictolerances using 2D imaging device forquality assurance

Cutting Samples

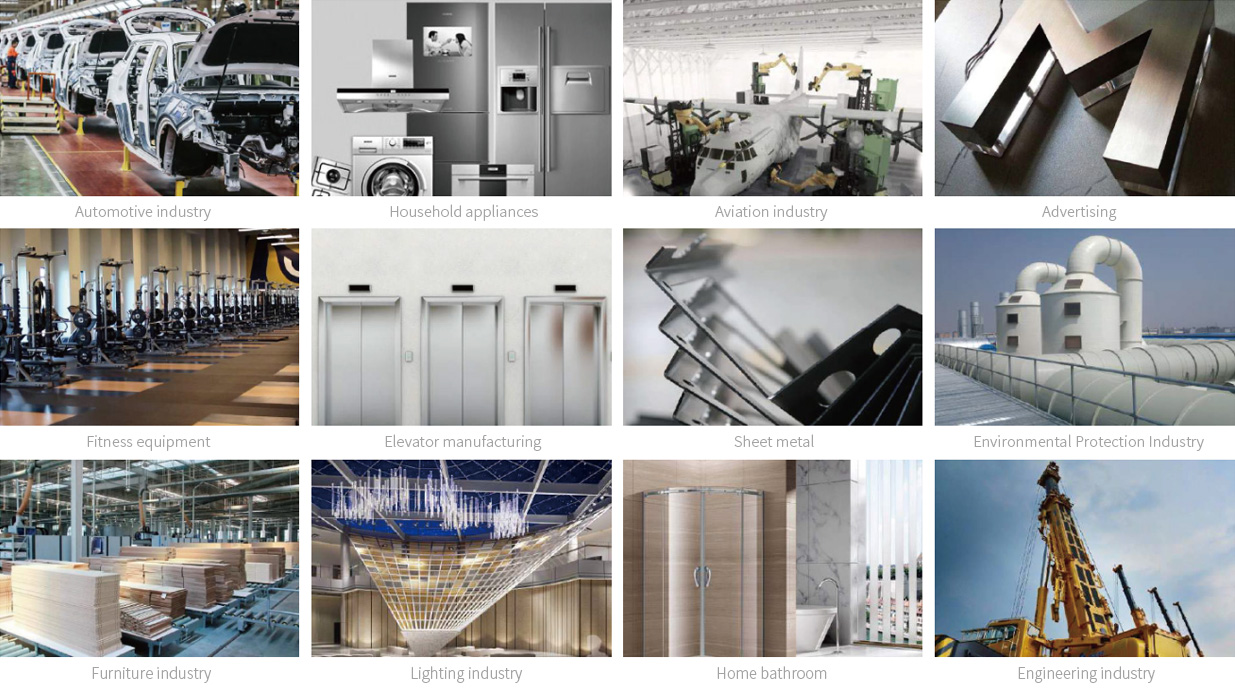

Application scenarios

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

Laser cutting machine: able to cut a variety of metal plates, mainly suitable for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, aluminum, various alloy plates, and other metal materials; widely used in: kitchen electrical, sheet metal Chassis frame, frame equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment,Various metal products, sheet metal cutting and other industries.

ASK FOR THE BEST PRICE Send Us A Message

Fill in your information

Contact information

+86-750-3582689

Address

Address: No.19,Gaoxin West Road,

Jianghai District, Jiangmen City,

Guangdong Province, China. P.C. 529085

Working hours

8:30 A.M.-12:00 A.M.

2:00 P.M.-6:00 P.M.